The INFINITE project took center stage at JEC World 2025, the leading international trade fair for composite materials, held in Paris from March 5 to 7. With its strong presence across multiple stands and participation in the JEC Composites Research & Innovation Projects program, INFINITE reaffirmed its role as a key European initiative driving the digital transformation of aerospace composites.

Throughout the three-day event, several project partners — including Teijin, Gaiker, Titania, Collins Aerospace and IDEKO — showcased their contributions to the project at their own booths, offering attendees the opportunity to learn more about the innovations developed in INFINITE’s 36-month journey.

HIGHLIGHTS OF THE PROJECT’S PRESENCE AT JEC 2025

Peio Olaskoaga, project coordinator from IDEKO, presented INFINITE during the official R&I Projects session, highlighting major advancements such as:

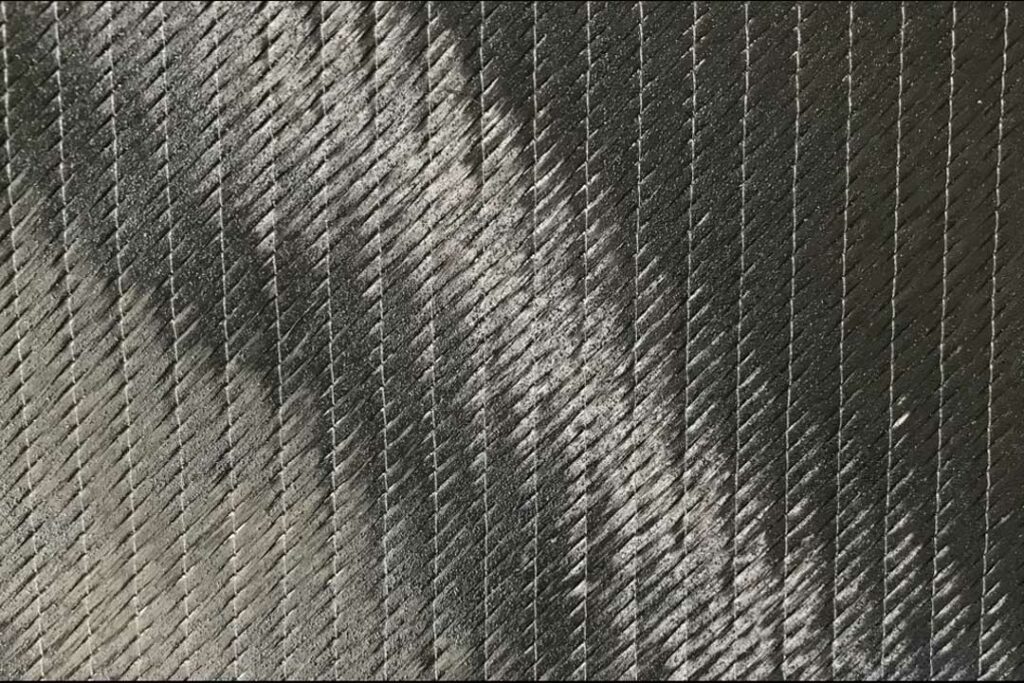

- The integration of wireless microwire sensors for real-time monitoring of key manufacturing stages (lay-up, preforming, infusion, and curing).

- The development of smart composite solutions to boost traceability and quality control in aerospace part production.

In a series of exclusive video interviews recorded during the event, partners shared their experiences, results, and vision for the project’s final phase:

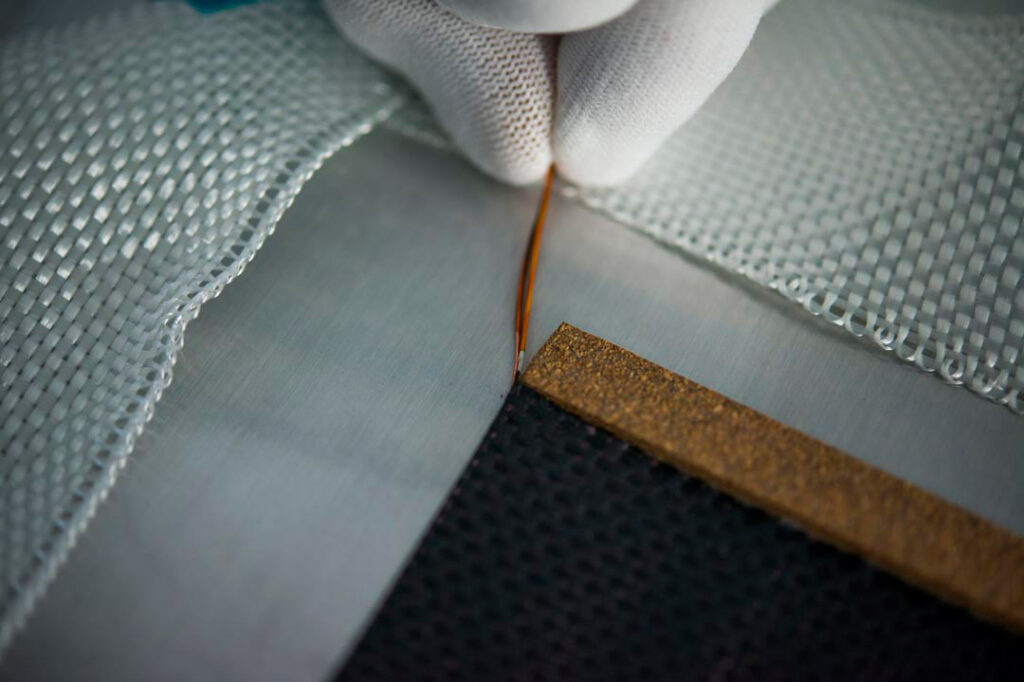

- Aeroform Composites introduced a new repair methodology and toolkit for NCF structures, including a custom-built stepping tool and a remote-controlled web app, achieving up to 85% of original strength in repaired parts.

- Collins Aerospace presented its work applying AI and machine learning for defect detection, building physics-informed algorithms capable of identifying delamination, dents, and cracks from microwire sensor data — with the goal of supporting predictive maintenance and reducing unplanned downtime.

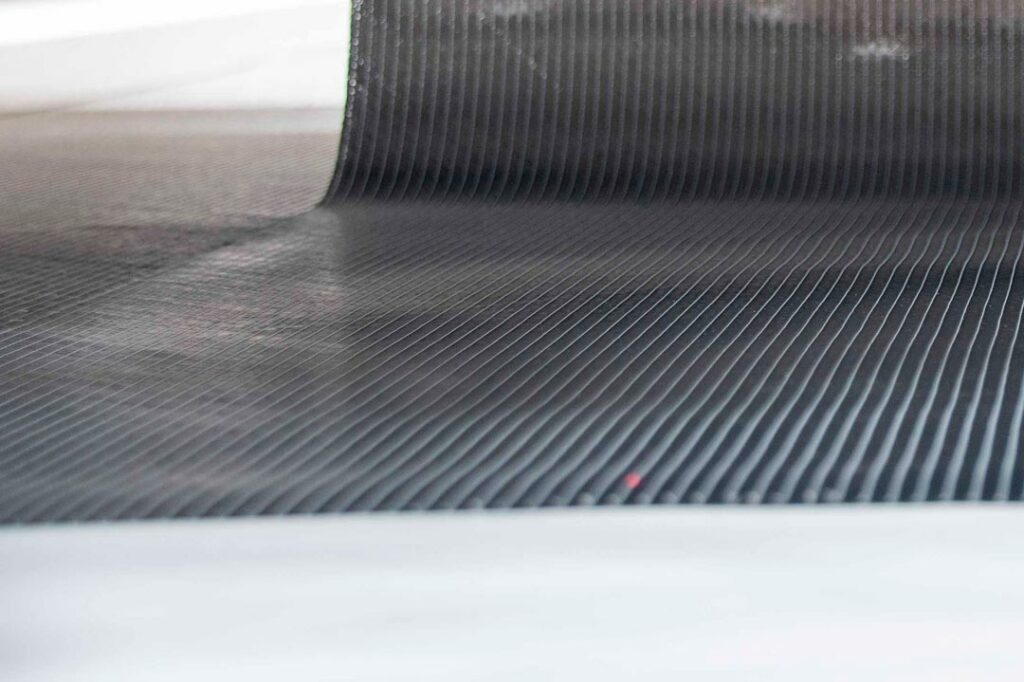

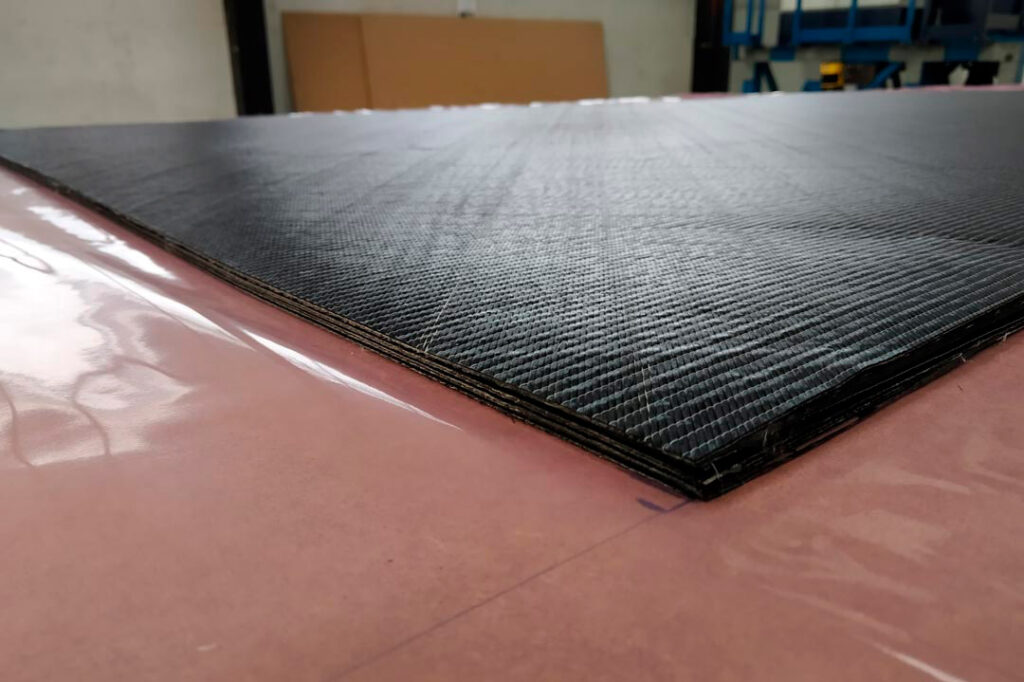

- Teijin shared their achievement in embedding microwires at industrial scale in NCF materials using a 100-inch-wide production line, adapting their processes to meet sensor integration needs. They emphasized the value of cross-border collaboration and confirmed the long-term potential of the technology beyond the project’s scope.

- GAIKER explained their dual role: monitoring sensorised composites under mechanical stress with a portable device, and confirming that microwires can be cleanly separated through pyrolysis, ensuring the recyclability of the materials. They look forward to expanding their work into glass-fibre composites.

- Titania reflected on the progress made and their continued work on optimizing the third-generation microwire reader. They confirmed the viability of microwires for structural health monitoring and expressed their interest in further exploring this technology in thermoplastic composites within future EU projects.

- IDEKO, project coordinator, presented INFINITE in the official R&I Projects area and at their booth, showcasing the project’s overall progress and engaging directly with stakeholders. With the project in its final stretch, IDEKO emphasized the relevance of these solutions for the future of aerospace composite manufacturing.

A KEY MOMENT IN THE PROJECT’S FINAL STRETCH

With only a few months left before completion, JEC 2025 has been a milestone moment to showcase results, connect with stakeholders and reinforce the visibility of the project at international level. The exchange of knowledge and feedback received during the fair will serve as a valuable input for the final validation and exploitation of the project outcomes.