The INFINITE – EU Project, focused on advancing smart manufacturing and digital monitoring solutions for aerospace composites, continues to make significant progress thanks to the contributions of its partners. One of the key players in this journey is Collins Aerospace, whose work is pioneering the use of artificial intelligence (AI) and machine learning (ML) to enhance the detection and quantification of damage in composite structures.

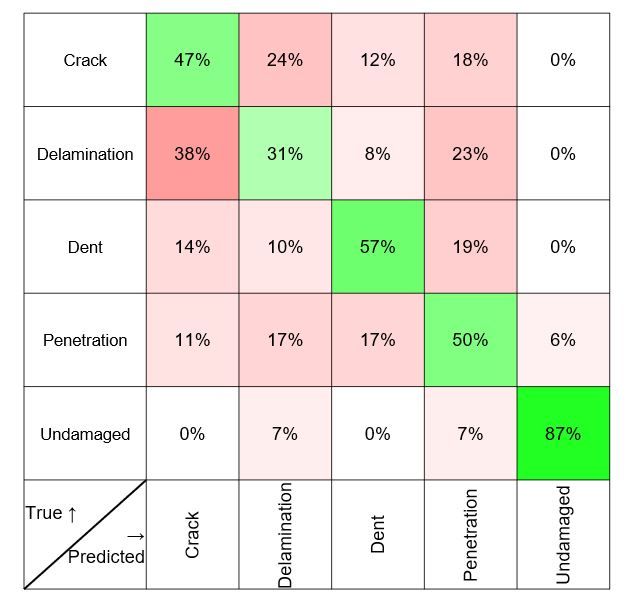

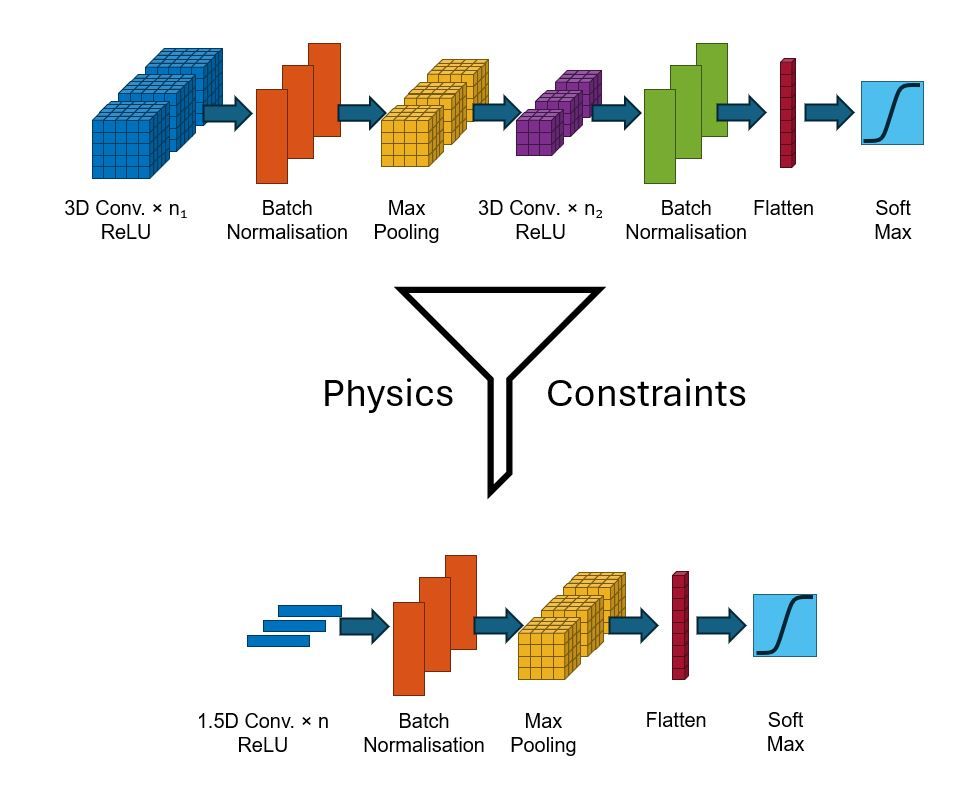

Monitoring the structural integrity of composite components is a complex challenge, given the variety of potential failure modes such as delamination, cracks, dents, and fiber breakage. Collins Aerospace’s role within INFINITE focuses on addressing this challenge by developing robust, physics-informed AI algorithms. These models are trained using both experimental data and simulated results derived from microwire sensor readings on composite coupons.

One of the most significant obstacles the team has tackled is working with low signal-to-noise ratios in sensor responses. To overcome this, Collins Aerospace has employed advanced algorithmic techniques to extract meaningful patterns from the data, ensuring the reliability and accuracy required for aerospace applications.

The potential impact of this work is substantial. Structural health monitoring of critical aerospace components such as fan cowls, thrust reversers, and inlet barrels will enable airlines to predict and schedule maintenance with greater efficiency. This could lead to a notable reduction in unscheduled maintenance costs and help minimize operational disruptions — a key factor in an industry where delays due to maintenance issues cost billions annually.

Beyond technical development, this work underscores the value of collaboration within European projects. As part of the INFINITE consortium, Collins Aerospace brings deep expertise and cutting-edge innovation, helping to drive forward new standards in smart monitoring and composite manufacturing technologies.

At INFINITE, we are proud to have Collins Aerospace as a partner and look forward to seeing these innovations evolve and transfer to industrial applications.