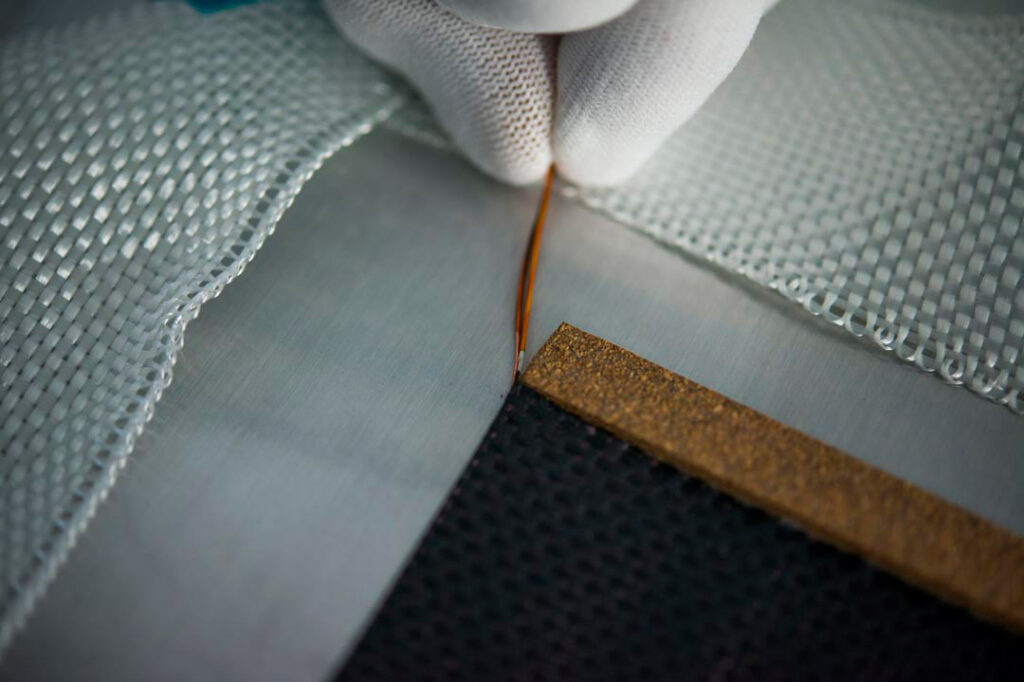

Over the past few months, Titania has been focused on developing and carrying out a test plan aimed at evaluating the properties of composite materials incorporating microwires. Leveraging its extensive expertise in characterization test plans, Titania has been able to explore new opportunities provided by the INFINITE project, particularly the application of non-contact analysis techniques.

In the aeronautical sector, strain gauges are a primary method for measuring strain during mechanical testing. However, their compatibility with ferromagnetic microwires is limited due to potential electromagnetic interference during measurements. To address this challenge, the INFINITE project has adopted Digital Image Correlation (DIC), a non-contact technique that measures deformation and strain by tracking a speckle pattern applied to the material’s surface.

Using DIC offers significant advantages, including the ability to calculate mechanical properties by creating virtual gauges and inputting load values from the testing machine into the software. Comparative in-plane shear tests have shown that results obtained through DIC are consistent with those from traditional strain gauges.

As part of the ongoing test plan, DIC will play a key role in determining the mechanical properties of sensorized composites. Its use will allow seamless integration with the portable reader used to monitor microwires, eliminating interference issues associated with strain gauges and enabling accurate and efficient measurements.